Surface Acoustic Wave (SAW) RF Filters: The Unsung Heroes Powering Next-Gen Wireless Networks. Discover the Science, Innovation, and Market Impact Behind This Game-Changing Technology.

- Introduction to Surface Acoustic Wave (SAW) RF Filters

- How SAW RF Filters Work: Principles and Technology

- Key Advantages Over Competing RF Filter Technologies

- Applications in Modern Wireless Communication Systems

- Recent Innovations and Emerging Trends in SAW RF Filters

- Market Landscape and Leading Manufacturers

- Challenges and Limitations Facing SAW RF Filters

- Future Outlook: SAW RF Filters in 5G, IoT, and Beyond

- Conclusion: The Lasting Impact of SAW RF Filters on Connectivity

- Sources & References

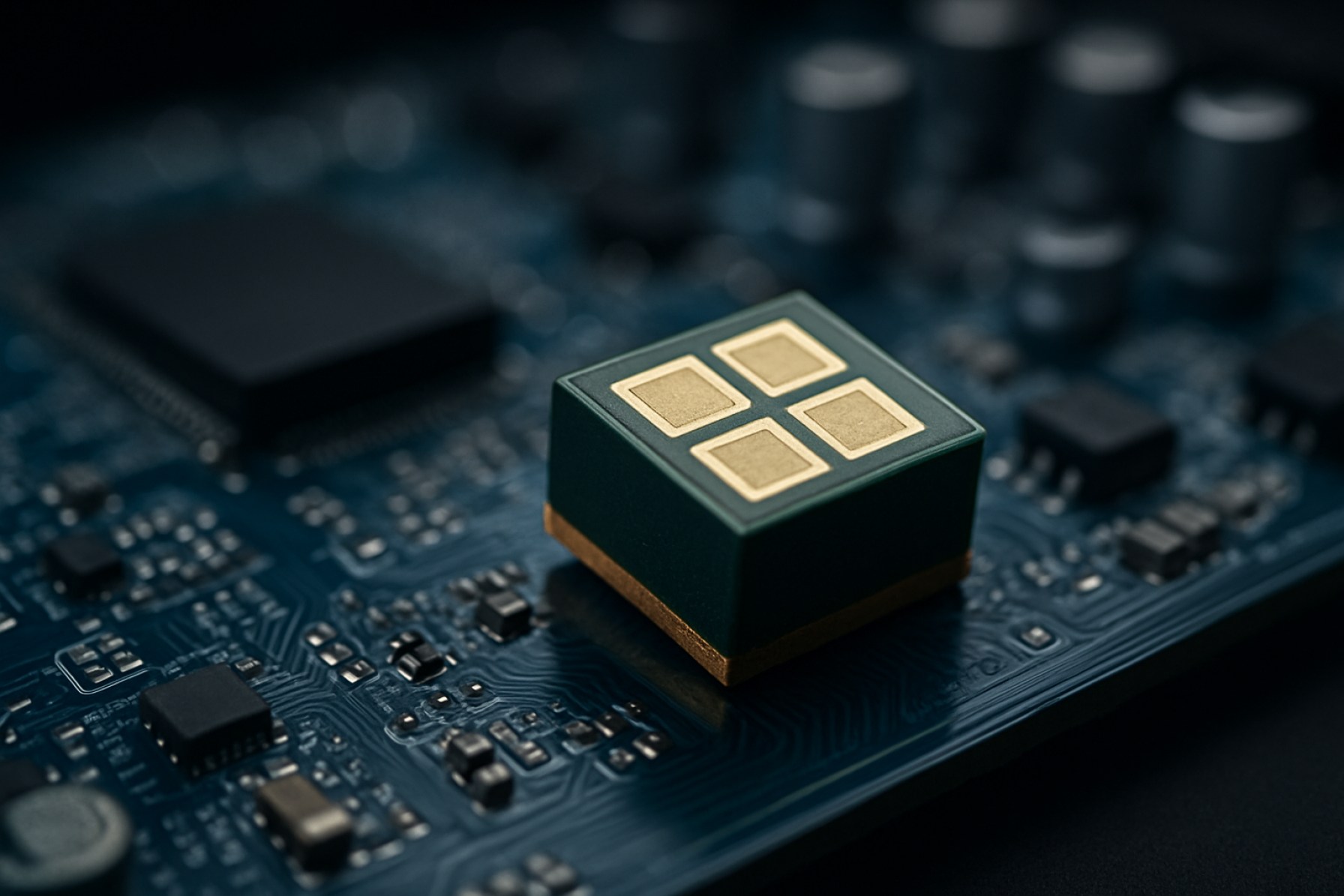

Introduction to Surface Acoustic Wave (SAW) RF Filters

Surface Acoustic Wave (SAW) RF filters are critical components in modern wireless communication systems, enabling the selection and separation of specific frequency bands within increasingly crowded radio frequency (RF) spectra. These filters utilize the propagation of acoustic waves along the surface of a piezoelectric substrate to achieve frequency-selective filtering, offering advantages in terms of size, cost, and performance for a wide range of applications, including mobile phones, wireless LANs, and satellite communications. The core principle involves converting electrical signals into mechanical (acoustic) waves via interdigital transducers (IDTs), which then travel across the substrate and are reconverted into electrical signals, with the device’s geometry and material properties determining the filter’s frequency response.

SAW RF filters are particularly valued for their compactness and ability to be mass-produced using photolithographic techniques, making them highly suitable for integration into portable and high-volume consumer electronics. Their frequency range typically spans from tens of megahertz to several gigahertz, covering most commercial wireless communication bands. However, SAW filters are generally more effective at lower frequencies compared to their bulk acoustic wave (BAW) counterparts, which are preferred for higher-frequency applications due to their superior power handling and temperature stability.

The ongoing evolution of wireless standards, such as 5G and Wi-Fi 6, continues to drive innovation in SAW filter design, focusing on improved selectivity, lower insertion loss, and enhanced miniaturization. As a result, SAW RF filters remain a foundational technology in the RF front-end modules of contemporary communication devices Murata Manufacturing Co., Ltd., Qorvo, Inc..

How SAW RF Filters Work: Principles and Technology

Surface Acoustic Wave (SAW) RF filters operate based on the conversion of electrical signals into mechanical (acoustic) waves and back, utilizing the piezoelectric effect. The core of a SAW filter is a piezoelectric substrate, typically made from materials such as quartz, lithium niobate, or lithium tantalate. On this substrate, interdigitated transducers (IDTs) are patterned using photolithography. When an RF signal is applied to the input IDT, it generates surface acoustic waves that propagate along the substrate’s surface. These waves are then received by the output IDT, which converts the mechanical energy back into an electrical signal.

The frequency response of a SAW filter is determined by the geometry and spacing of the IDTs, which act as frequency-selective elements. By carefully designing the finger spacing and layout, engineers can tailor the filter’s center frequency and bandwidth to meet specific requirements. SAW filters are inherently suitable for high-frequency applications, typically ranging from tens of MHz to several GHz, making them ideal for mobile communications, television broadcasting, and wireless networking.

One of the key advantages of SAW technology is its ability to provide sharp filtering characteristics in a compact form factor, with low insertion loss and high selectivity. However, SAW filters can be sensitive to temperature variations and may exhibit performance degradation at very high frequencies compared to other technologies like Bulk Acoustic Wave (BAW) filters. Despite these limitations, SAW RF filters remain a cornerstone in RF front-end design due to their cost-effectiveness and mature manufacturing processes (Murata Manufacturing Co., Ltd.; Qorvo, Inc.).

Key Advantages Over Competing RF Filter Technologies

Surface Acoustic Wave (SAW) RF filters offer several key advantages over competing RF filter technologies, such as Bulk Acoustic Wave (BAW) filters, ceramic filters, and LC (inductor-capacitor) filters. One of the most significant benefits is their compact size and low profile, which make SAW filters particularly well-suited for integration into space-constrained devices like smartphones, tablets, and IoT modules. The planar fabrication process used in SAW technology enables high-volume, cost-effective manufacturing, further driving their widespread adoption in consumer electronics Murata Manufacturing Co., Ltd..

SAW filters also excel in terms of frequency selectivity and low insertion loss within their optimal frequency range (typically up to 2.5–3 GHz). This makes them ideal for applications in the sub-3 GHz spectrum, such as GSM, LTE, and Wi-Fi bands, where sharp filtering and minimal signal attenuation are critical Qorvo, Inc.. Additionally, SAW filters exhibit excellent temperature stability and repeatability, ensuring consistent performance across varying environmental conditions.

Compared to LC and ceramic filters, SAW filters provide superior miniaturization and integration capabilities, allowing for more complex and multi-band filtering solutions in a single package. While BAW filters may outperform SAW at higher frequencies, the cost-effectiveness, ease of integration, and mature manufacturing ecosystem of SAW filters continue to make them the preferred choice for many RF front-end designs TDK Corporation.

Applications in Modern Wireless Communication Systems

Surface Acoustic Wave (SAW) RF filters play a pivotal role in modern wireless communication systems, enabling efficient frequency selection and signal processing in increasingly crowded spectral environments. Their compact size, low insertion loss, and high selectivity make them indispensable in devices such as smartphones, tablets, and IoT modules, where space and power efficiency are critical. SAW filters are extensively used in front-end modules of mobile handsets to separate transmit and receive bands, ensuring minimal interference and optimal signal clarity. For instance, in 4G and 5G networks, SAW filters help manage the complex coexistence of multiple frequency bands, supporting carrier aggregation and advanced modulation schemes required for high data rates and reliable connectivity.

Beyond mobile devices, SAW RF filters are integral to wireless infrastructure equipment, including base stations and small cells, where they contribute to channel selection and noise suppression. Their application extends to Wi-Fi routers, Bluetooth devices, and GPS receivers, where precise filtering is essential for robust performance in environments with overlapping signals. The automotive industry also leverages SAW filters in vehicle-to-everything (V2X) communication systems, supporting advanced driver-assistance systems (ADAS) and autonomous driving technologies.

The ongoing evolution of wireless standards and the proliferation of connected devices continue to drive innovation in SAW filter design, with research focusing on improving temperature stability, miniaturization, and integration with other RF components. As a result, SAW RF filters remain a cornerstone technology in the advancement of modern wireless communication systems, ensuring reliable and high-quality signal transmission across diverse applications (Murata Manufacturing Co., Ltd., Qorvo).

Recent Innovations and Emerging Trends in SAW RF Filters

Recent years have witnessed significant advancements in Surface Acoustic Wave (SAW) RF filter technology, driven by the escalating demands of 5G, IoT, and advanced wireless communication systems. One notable innovation is the development of temperature-compensated SAW (TC-SAW) filters, which utilize novel piezoelectric substrates and layered structures to minimize frequency drift caused by temperature fluctuations. This enhancement is crucial for maintaining signal integrity in environments with varying thermal conditions, as highlighted by Murata Manufacturing Co., Ltd..

Another emerging trend is the integration of SAW filters with advanced packaging techniques, such as wafer-level chip-scale packaging (WLCSP), which enables further miniaturization and improved performance. This approach supports the ongoing trend toward smaller, more power-efficient mobile devices and wearables, as detailed by Qorvo, Inc.. Additionally, the use of new piezoelectric materials, such as lithium tantalate (LiTaO3) and lithium niobate (LiNbO3), has led to improved filter selectivity and lower insertion loss, making SAW filters more competitive in high-frequency applications.

Furthermore, the integration of artificial intelligence (AI) and machine learning (ML) in the design and optimization of SAW filters is gaining traction. These technologies enable rapid prototyping and performance prediction, reducing development cycles and enhancing filter characteristics. As wireless standards continue to evolve, the adaptability and scalability of SAW RF filters will remain a focal point for research and commercial innovation, as noted by TDK Corporation.

Market Landscape and Leading Manufacturers

The market for Surface Acoustic Wave (SAW) RF filters has experienced robust growth, driven by the proliferation of wireless communication devices, the expansion of 4G and 5G networks, and the increasing demand for high-performance, cost-effective filtering solutions in consumer electronics and automotive applications. SAW RF filters are widely adopted in smartphones, tablets, IoT devices, and wireless infrastructure due to their compact size, low cost, and reliable frequency selectivity. The Asia-Pacific region, particularly China, South Korea, and Japan, dominates both the production and consumption of SAW filters, owing to the presence of major electronics manufacturers and a strong supply chain ecosystem.

The competitive landscape is characterized by a mix of established multinational corporations and specialized component manufacturers. Leading players include Murata Manufacturing Co., Ltd., TDK Corporation, and Skyworks Solutions, Inc., all of which offer a broad portfolio of SAW RF filters for various frequency bands and applications. Other significant contributors are Qorvo, Inc. and TAIYO YUDEN CO., LTD., both recognized for their innovation and integration capabilities. These companies invest heavily in research and development to enhance filter performance, miniaturization, and integration with other RF front-end components.

Market trends indicate a gradual shift towards hybrid solutions that combine SAW and Bulk Acoustic Wave (BAW) technologies to address the challenges of higher frequency bands and stringent performance requirements in next-generation wireless systems. Nevertheless, SAW RF filters remain indispensable for low- and mid-frequency applications, ensuring their continued relevance in the evolving RF component landscape.

Challenges and Limitations Facing SAW RF Filters

Despite their widespread adoption in wireless communication systems, Surface Acoustic Wave (SAW) RF filters face several challenges and limitations that impact their performance and applicability. One of the primary concerns is their sensitivity to temperature variations. The acoustic velocity in piezoelectric substrates, such as quartz or lithium tantalate, changes with temperature, leading to frequency drift and reduced filter stability. This can be particularly problematic in environments with fluctuating temperatures, necessitating additional compensation techniques or the use of temperature-stable materials, which may increase costs and complexity (Murata Manufacturing Co., Ltd.).

Another significant limitation is the relatively high insertion loss compared to other filter technologies, such as Bulk Acoustic Wave (BAW) filters. This loss is primarily due to the energy dissipation in the substrate and the electrodes, which can degrade signal strength and overall system efficiency. Additionally, SAW filters are generally less suitable for high-frequency applications above 2.5 GHz, as their performance deteriorates due to increased acoustic losses and reduced electromechanical coupling efficiency at higher frequencies (Qorvo, Inc.).

SAW filters also face challenges related to miniaturization and integration. As wireless devices become smaller and more complex, integrating SAW filters with other components on a single chip becomes increasingly difficult due to their reliance on specific substrate materials and fabrication processes. Furthermore, their susceptibility to electromagnetic interference and spurious responses can limit their use in densely packed RF environments (TDK Corporation).

Future Outlook: SAW RF Filters in 5G, IoT, and Beyond

The future of Surface Acoustic Wave (SAW) RF filters is closely tied to the rapid evolution of wireless communication technologies, particularly 5G and the Internet of Things (IoT). As 5G networks demand higher frequencies, wider bandwidths, and lower latency, SAW filters are being pushed to their performance limits. While traditionally favored for their compact size, low cost, and high selectivity in sub-3 GHz applications, SAW filters are now being innovatively engineered to address the stringent requirements of 5G front-end modules, especially in the sub-6 GHz spectrum. Advanced materials, such as lithium tantalate and lithium niobate, are being explored to enhance temperature stability and power handling, ensuring reliable operation in increasingly complex RF environments.

In the IoT domain, the proliferation of connected devices necessitates highly integrated, low-power, and cost-effective RF solutions. SAW filters, with their mature manufacturing processes and proven reliability, are well-positioned to support the massive deployment of IoT sensors and modules. Furthermore, ongoing research into hybrid filter technologies—combining SAW with Bulk Acoustic Wave (BAW) or other resonator types—aims to extend the operational frequency range and improve performance metrics such as insertion loss and out-of-band rejection.

Looking beyond 5G and IoT, the continued miniaturization of electronics and the emergence of new wireless standards will drive further innovation in SAW filter design and integration. Industry leaders and research institutions are investing in next-generation SAW technologies to meet the demands of future wireless ecosystems, as highlighted by Murata Manufacturing Co., Ltd. and Qorvo, Inc..

Conclusion: The Lasting Impact of SAW RF Filters on Connectivity

Surface Acoustic Wave (SAW) RF filters have played a pivotal role in shaping the landscape of modern wireless communication. Their unique ability to provide precise frequency selection, compact form factor, and cost-effective mass production has made them indispensable in a wide array of devices, from smartphones to IoT sensors. The ongoing evolution of wireless standards, such as 5G and beyond, continues to demand high-performance filtering solutions, and SAW filters have consistently adapted to meet these requirements through innovations in materials and design techniques.

The lasting impact of SAW RF filters is evident in their widespread adoption across consumer electronics, automotive systems, and industrial applications. Their integration has enabled higher data rates, improved signal integrity, and reduced interference, all of which are critical for reliable connectivity in increasingly crowded radio frequency environments. Furthermore, the continued research and development in this field, supported by organizations like the Institute of Electrical and Electronics Engineers (IEEE) and the International Telecommunication Union (ITU), ensures that SAW technology remains at the forefront of RF filtering solutions.

In conclusion, the enduring relevance of SAW RF filters lies in their adaptability, performance, and scalability. As the demand for seamless, high-speed wireless connectivity grows, SAW filters will remain a cornerstone technology, enabling the next generation of communication systems and supporting the global expansion of connected devices.

Sources & References

- Murata Manufacturing Co., Ltd.

- Skyworks Solutions, Inc.

- Institute of Electrical and Electronics Engineers (IEEE)

- International Telecommunication Union (ITU)