The world of robotics is entering a new era! In a significant advancement, the Korea Atomic Energy Research Institute (KAERI) has collaborated with Victex, a robotics company, to advance technologies that will enhance nuclear decommissioning efforts.

The agreement between KAERI and Victex involves a financial transaction valued at approximately KRW180 million, equivalent to around USD125,000. This deal encompasses vital components like the robot’s manipulator, the sophisticated control system, remote operation technology, and five pivotal patents. Victex intends to leverage these technological assets to create an innovative decontamination robot that integrates its existing radioactive waste management systems with the advanced capabilities of the Armstrong robot.

Since 2015, a dedicated research team has been developing robotic solutions for nuclear emergencies, with the Armstrong robot making its debut in government disaster training exercises in 2024. A complementary agreement with Korea Expressway Corporation is set to enhance the robot’s usability in hazardous areas such as highways.

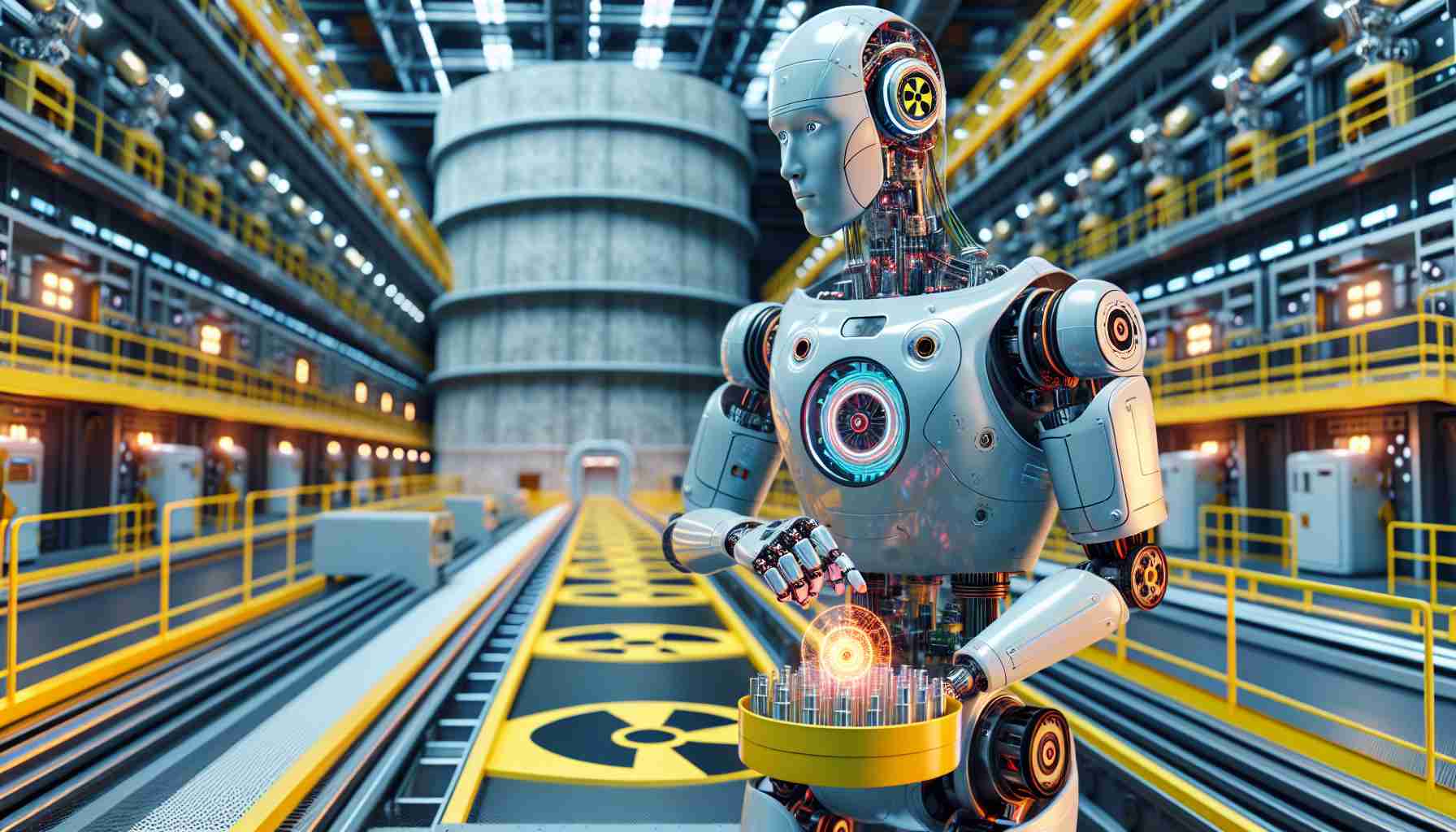

The Armstrong robot features caterpillar tracks for navigating rough surfaces and can perform intricate movements with various tools. The KAERI president highlighted the importance of this technology transfer, emphasizing its potential to revolutionize nuclear power plant decommissioning. As the global market for nuclear decommissioning grows, KAERI remains committed to expanding robotics technology beyond its current applications.

The Broader Implications of Advancements in Robotics for Nuclear Decommissioning

The partnership between the Korea Atomic Energy Research Institute (KAERI) and Victex signals a pivotal moment not only for nuclear safety but also for the future of robotic technology in hazardous environments. As societies increasingly turn towards nuclear energy, the successful decommissioning of aging plants represents a critical societal challenge. This advancement in robotics could significantly enhance safety and efficiency, thereby shaping public perception and trust in nuclear energy’s viability as a sustainable alternative.

From a cultural perspective, the integration of robotics into nuclear decommissioning tasks can lead to a shift in how we approach environmental stewardship. The ability to remotely manage hazardous materials reduces human risk, aligning with a growing societal demand for sustainable practices. As this technology matures, it prompts a reevaluation of human roles in dangerous industries, potentially leading to greater acceptance and adoption of robotic systems across various sectors.

Economically, the burgeoning global market for nuclear decommissioning—estimated to reach several billion dollars—offers profound implications. The introduction of cost-effective, efficient robotic systems can significantly lower operational costs and timeframes associated with decommissioning, directly influencing global energy markets. As countries invest more in robotic solutions, the global economy may see a ripple effect, creating jobs focused on robotics engineering, environmental science, and disaster management.

Finally, the environmental impacts cannot be overstated. The deployment of advanced robots like the Armstrong not only improves operational safety but also enhances the efficacy of contamination management and waste reduction. As this robotic technology evolves, it stands to play a crucial role in setting new standards for environmental protection in nuclear decommissioning efforts. Emphasizing innovation in this sector not only addresses immediate safety concerns but also lays the groundwork for a healthier planet for future generations.

Revolutionizing Nuclear Decommissioning: The Future of Robotics is Here!

The Transition to Advanced Robotics in Nuclear Decommissioning

The world of robotics is experiencing a remarkable transformation, particularly in the field of nuclear decommissioning. The collaboration between the Korea Atomic Energy Research Institute (KAERI) and Victex represents a critical step forward, focusing on developing state-of-the-art robotic technologies that will redefine how nuclear facilities are dismantled safely and efficiently.

Key Features of the Armstrong Robot

The Armstrong robot, central to this initiative, is engineered for versatility and resilience. Here are its standout features:

– Caterpillar Tracks: Designed for superior mobility across rough and uneven terrain, making it suitable for various environments.

– Advanced Manipulation Capabilities: Equipped with sophisticated tools, the Armstrong robot can execute delicate operations, essential for handling hazardous materials.

– Remote Operation Technology: Ensures safe distance operations, allowing human operators to control the robot from a secure location.

Use Cases in Nuclear Decommissioning

1. Emergency Response: The Armstrong robot is set to play a crucial role in emergency scenarios, allowing for rapid response in the event of nuclear incidents.

2. Decontamination Processes: With its robotic manipulator and advanced control systems, the robot can perform decontamination tasks more efficiently than traditional methods.

3. Hazardous Area Operations: Collaborations with partners like Korea Expressway Corporation aim to utilize the Armstrong robot in environments that are difficult for humans to operate, such as contaminated highway sites.

Advantages of Robotic Assistance in Nuclear Decommissioning

– Increased Safety: Robots significantly reduce the exposure of human workers to harmful radiation by performing tasks in high-risk environments.

– Cost Efficiency: While the initial investment in robotic technology may be high, the long-term savings in labor and safety costs can be substantial.

– Enhanced Precision: Robots are designed for accuracy, minimizing the risk of accidents and ensuring compliance with regulatory standards.

Limitations and Challenges

Despite the promising advancements, there are challenges associated with deploying robotic technology in nuclear settings:

– High Development Costs: The initial financial outlay, as seen with the KRW180 million investment, can be a hurdle for widespread adoption.

– Technical Complexity: Implementing and maintaining advanced robotics systems requires specialized knowledge and training.

– Regulatory Hurdles: Navigating the complex regulations surrounding nuclear operations can slow the integration of new technologies.

Future Trends and Predictions

As the market for nuclear decommissioning continues to expand, the demand for robotic solutions is expected to grow. Innovations in artificial intelligence and machine learning will likely augment the capabilities of robots like Armstrong, increasing their intelligence in hazardous operations. Furthermore, the integration of eco-friendly technologies in robotic designs may promote sustainability in nuclear decommissioning efforts.

Conclusion

The collaboration between KAERI and Victex marks a significant milestone in the evolution of robotics for nuclear decommissioning. As technologies mature and regulatory challenges are addressed, we can anticipate a future where robots play an even larger role in ensuring the safety and efficacy of decommissioning operations.

For more insights on robotics and nuclear technology, visit KAERI.

The source of the article is from the blog portaldoriograndense.com